Top MTU Engine Parts Manufacturers: Quality and Reliability

In the competitive landscape of engine manufacturing, the demand for quality parts is paramount. Specifically, when it comes to MTU engine parts manufacturers, the market is flooded with options, but not all are created equal. This article delves into the leading manufacturers who are shaping the future of diesel engines and generators, ensuring that businesses have access to reliable components for their operational needs.

Why MTU Engine Parts Are Essential

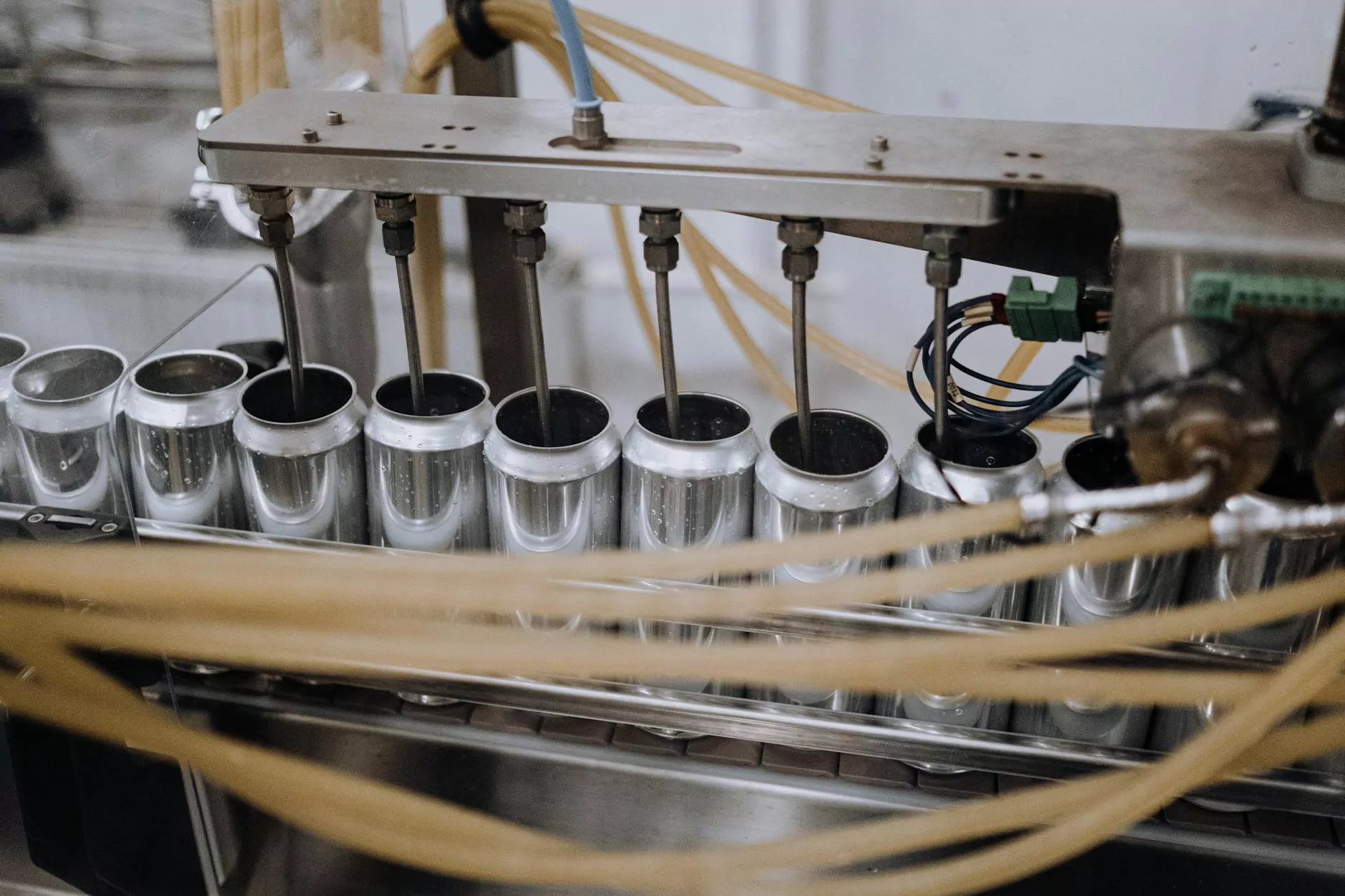

MTU engines are renowned for their robustness and efficiency, widely used in various industries, including marine, rail, power generation, and industrial applications. The components that make up these engines are crucial for their performance and longevity. Here’s why choosing the right manufacturer is vital:

- Performance: High-quality parts ensure that engines run efficiently, minimizing downtime.

- Durability: Quality components withstand harsh operating conditions.

- Cost-effectiveness: Reliable parts reduce the frequency of replacements, saving businesses money in the long run.

- Compliance: Ensuring parts meet regulatory standards to avoid legal issues.

Understanding the Market for MTU Engine Parts

The market for MTU engine parts has evolved significantly. Businesses are no longer looking for just any parts; they are seeking out suppliers who can guarantee quality, reliability, and fast delivery times. Let’s explore the factors that play a role in the selection of an MTU engine parts manufacturer:

1. Reputation and Trust

Choosing a manufacturer with a strong reputation in the industry provides peace of mind. Customers often turn to reviews, testimonials, and case studies to assess a manufacturer’s reliability. The top MTU engine parts manufacturers have built their reputations over years of consistent performance and customer satisfaction.

2. Quality Assurance Processes

Quality assurance is a crucial element. Leading manufacturers implement rigorous testing and quality control protocols to ensure that every part meets high standards. Look for certifications such as ISO and adherence to industry standards as indicators of a manufacturer's commitment to quality.

3. Range of Products Offered

The diversification of parts offered is essential. Reliable manufacturers provide a comprehensive range of components, which can include:

- Engine Blocks

- Cylinders

- Fuel Systems

- Turbos and Superchargers

- Electronic Control Units

This variety allows businesses to source all necessary parts from a single supplier, streamlining operations and reducing lead times.

Top MTU Engine Parts Manufacturers to Consider

Now, let’s delve into some of the most reputable MTU engine parts manufacturers in the market.

1. Engine Family LLC

Engine Family LLC stands out as a leading manufacturer and supplier of MTU engine parts. With a commitment to quality and customer service, they offer a vast selection of components designed to meet the demands of various industries. Their expertise in both diesel engine manufacturing and being a diesel generator supplier gives them an edge in understanding customer needs.

2. MTU Friedrichshafen GmbH

The original manufacturer of MTU engines, MTU Friedrichshafen GmbH, provides authentic parts and cutting-edge technology. Their commitment to innovation and quality makes them a go-to source for businesses looking for original equipment manufacturer (OEM) parts.

3. Cummins Inc.

While primarily known for their own engine systems, Cummins Inc. manufactures and sells a variety of replacement parts for MTU engines, positioned perfectly for businesses looking for versatile solutions in engine management.

4. ZF Friedrichshafen AG

Known for their engineering excellence, ZF Friedrichshafen AG produces a range of components that complement MTU engines, particularly in the realms of propulsion and transmission systems.

The Importance of Aftermarket Parts

Beyond OEM components, the aftermarket parts industry plays a significant role. Many businesses rely on aftermarket suppliers to find cost-effective alternatives without sacrificing quality. Here are a few reasons to consider reputable aftermarket manufacturers:

- Cost Savings: Aftermarket parts are often more affordable than OEM parts.

- Availability: Many aftermarket manufacturers maintain extensive inventories, ensuring quick access to essential components.

- Innovation: Some aftermarket suppliers invest heavily in R&D to improve upon original designs.

How to Choose the Right MTU Engine Parts Manufacturer

With so many options available, selecting the right manufacturer requires careful consideration. Here are some key steps to guide your decision:

1. Research

Conduct thorough research on potential manufacturers. Look for reviews, case studies, and testimonials that speak to their reliability and quality.

2. Evaluate Product Range

Choose a manufacturer that offers the specific parts you require and can provide additional components in the future as your needs evolve.

3. Request Samples

If possible, request samples to evaluate the quality of the parts. This practical assessment can provide invaluable insights.

4. Assess Customer Service

Strong customer service is essential. A responsive manufacturer can help troubleshoot issues and provide guidance on parts selection and usage.

5. Compare Pricing

While price should not be the sole factor, it is important to compare costs among different manufacturers. Look for those who offer a good balance between pricing and quality.

The Future of MTU Engine Parts Manufacturing

The landscape of MTU engine parts manufacturing is set to evolve with advancements in technology. Innovations such as 3D printing and smart manufacturing processes are revolutionizing how parts are designed and produced. This evolution promises not only enhanced performance and durability but also shorter lead times and reduced costs for businesses.

1. 3D Printing

3D printing technology is increasingly being used to produce intricate engine components. This technology allows for rapid prototyping and the ability to create parts that are no longer in production. Manufacturers who adopt this technology can provide customized solutions tailored to specific customer needs.

2. Smart Manufacturing

Smart manufacturing involves the use of IoT and AI to streamline production processes. This results in improved efficiency, higher accuracy, and lower waste during production. Staying ahead of the curve will be key for manufacturers looking to maintain a competitive edge.

Conclusion

In conclusion, choosing the right MTU engine parts manufacturers is a critical decision for any business relying on diesel engines and generators. Quality parts not only enhance performance but also contribute significantly to the overall efficiency and longevity of machinery. By focusing on reputation, quality assurance, product range, and strong customer support, you can find a manufacturer that meets your needs and helps your business thrive.

For those in search of reliable MTU engine parts, look no further than Engine Family LLC, where quality meets expertise. In the fast-evolving engine marketplace, staying informed about the best manufacturers is essential for ensuring operational success.