Understanding Engine Bearing Cost: Essential Insights for Diesel Engine Parts

When it comes to diesel engines, the engine bearing cost is a crucial factor that impacts both performance and longevity. Understanding this cost can help you make informed decisions about your diesel engine parts and maintenance. In this article, we will explore the components of engine bearing costs, factors that influence pricing, and how to choose the best parts for your needs.

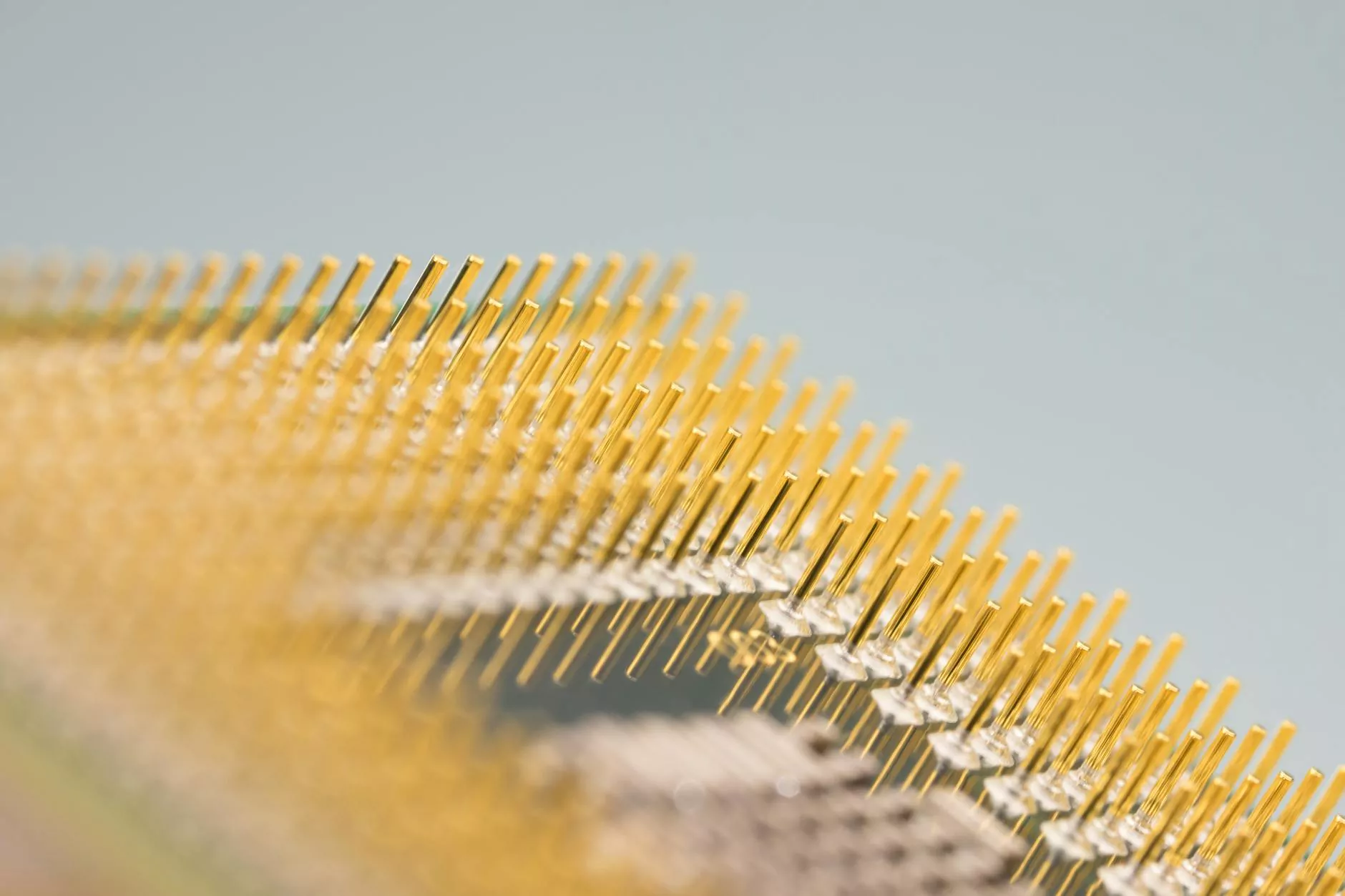

What Are Engine Bearings?

Engine bearings are essential components in a diesel engine, designed to support rotating shafts and manage friction. They play a critical role in ensuring that the engine runs smoothly and efficiently. The key functions of engine bearings include:

- Reducing Friction: Engine bearings minimize friction between moving parts, which helps to prevent wear and tear.

- Load Distribution: They distribute loads evenly across the crankshaft and other engine components, maintaining balance.

- Enhancing Durability: High-quality bearings enhance the overall durability of the engine, leading to longer service life.

Challenging Aspects of Engine Bearing Cost

Understanding the engine bearing cost involves recognizing that not all bearings are created equal. There are various factors that impact pricing, which can lead to significant variance based on several aspects:

1. Material Quality

The material used in manufacturing engine bearings greatly affects their durability and performance. Common materials include:

- Bronze: Offers great strength and resistance to wear.

- Plastic: Lightweight but may not last as long under heavy loads.

- Steel: Provides exceptional strength but might require lubrication for optimal performance.

Higher quality materials generally translate to a higher engine bearing cost, but they also contribute to improved engine longevity.

2. Bearing Types

Different types of engine bearings are designed for specific applications. The most common types include:

- Main Bearings: Support the crankshaft.

- Connecting Rod Bearings: Link the connecting rods to the crankshaft.

- Camshaft Bearings: Provide support to the camshaft.

Each type varies in price and quality, affecting the overall cost of engine bearings.

3. Brand Reputation

Purchasing bearings from reputable manufacturers often means higher prices. However, investing in recognized brands can result in:

- Increased Reliability: Renowned brands usually conduct extensive testing to ensure their products meet high standards.

- Better Warranties: Well-known brands often offer robust warranties, providing peace of mind.

The engine bearing cost from respected manufacturers may be higher, but the value often justifies the expense.

4. Application Specificity

The intended use of your engine bearings also determines the cost. Bearings for high-performance engines or specialized applications may incur additional charges due to their engineered complexity and material specifications.

Assessing the Total Engine Bearing Cost

The total engine bearing cost can be broken down into multiple components. Here are critical considerations when budgeting for your diesel engine services:

1. Purchase Price

The initial purchase price of the bearings is often what comes to mind first. It’s essential to consider both the low-end options and high-end parts. Opting for cheap bearings may save money upfront but could lead to higher costs later due to maintenance issues.

2. Installation Expenses

Incorporating professional installation into your budget is essential. Installation often requires skilled technicians, especially when handling performance engines. Remember that inadequate installation can lead to premature failure of the bearings.

3. Maintenance Costs

Long-term maintenance should also be factored into your overall engine bearing costs. Regular oil changes and monitoring wear can help prolong the life of your bearings while reducing future replacements.

4. Potential Downtime

Consider potential downtime as it can translate into significant losses in a business setting. Using high-quality bearings meant for specific performance purposes can reduce the chances of engine failures or breakdowns.

Choosing the Right Engine Bearings

With multiple aspects influencing the engine bearing cost, making an informed choice is paramount. Here are steps to ensure you select the best bearings for your diesel engine:

1. Assess Your Needs

Determine the type of engine you have and its performance requirements. For heavy-duty usage, select bearings designed for higher loads.

2. Do Your Research

Invest time in researching brands and customer reviews. Websites like client-diesel.com provide valuable information on various parts and suppliers.

3. Consult Professionals

When in doubt, consult with industry professionals or mechanics who can provide insights on the best options tailored to your specific engine type.

4. Consider Bulk Purchasing

If your business involves frequent maintenance or service, purchasing bearings in bulk could lead to significant cost savings.

Conclusion

Understanding the engine bearing cost is vital for anyone involved in the maintenance of diesel engines. By considering factors such as material quality, type of bearings, brand reputation, and specific application needs, you can make informed decisions that result in improved performance and longevity.

A well-constructed engine paired with the right bearings ensures efficiency and power, providing trust and reliability in your diesel engine's performance. Remember, investing in quality parts is an investment in the future of your engine.

To explore high-quality diesel engine parts and gain more insights into managing your engine bearing cost, visit client-diesel.com today!