The Importance of Camshaft Manufacturing in Diesel Engines

In the realm of diesel engine parts, few components are as crucial as the camshaft. This integral part plays a vital role in controlling engine timing and performance, making camshaft manufacturing an essential aspect of the automotive industry. Understanding its significance can lead to better engine performance, enhanced efficiency, and longer lifespan.

What is a Camshaft?

A camshaft is a rotating shaft that controls the opening and closing of the engine valves. It translates the linear motion of the engine into rotational motion, ensuring that fuel and air enter the combustion chamber at the right time. In diesel engines, where precision and efficiency are paramount, the quality of camshaft manufacturing can significantly influence overall engine performance.

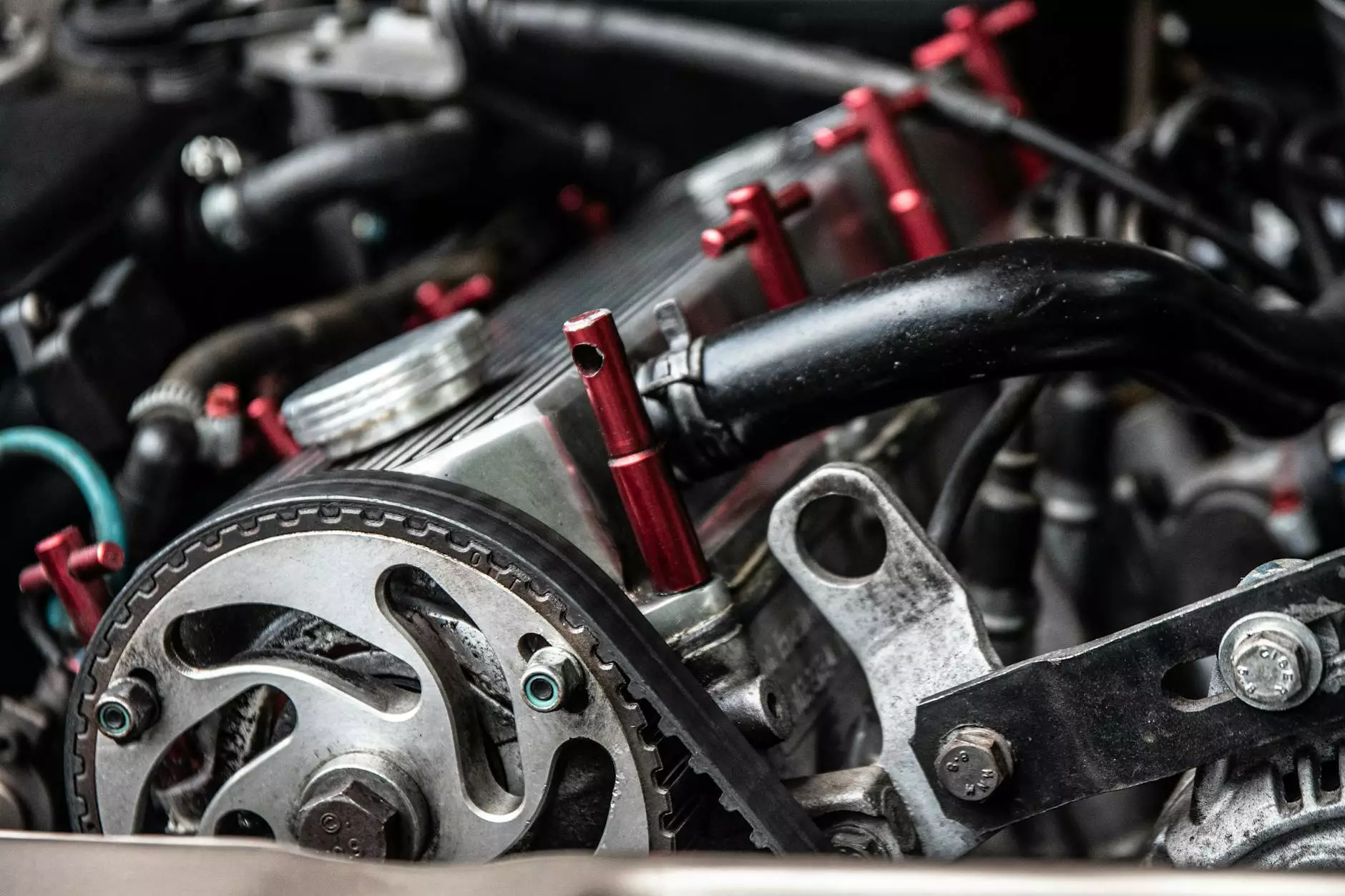

Components of a Camshaft

To appreciate the complexity of camshaft manufacturing, it’s essential to understand its components:

- Lobes: The protruding parts that push against the engine valves during rotation.

- Bearings: Support the shaft and allow smooth rotation.

- Gear Teeth: Connect the camshaft to other engine components, facilitating synchronization.

- Material: High-quality steel or cast iron is commonly used for durability and strength.

The Manufacturing Process of Camshaft

The process of camshaft manufacturing involves several critical stages to ensure optimal performance and durability:

1. Material Selection

Choosing the right material is crucial in camshaft manufacturing. The most common materials include:

- High Carbon Steel: Offers excellent hardness and wear resistance.

- Alloy Steels: Provide better ductility and strength.

- Cast Iron: Economical and suitable for various applications, though less common in performance engines.

2. Forging

Forge shaping is preferred in high-performance manufacturing because it aligns the grain structure of the material, resulting in stronger and more durable camshafts. The forging process involves:

- Heating the selected material to a malleable state.

- Using a die to shape the material into a rough camshaft form.

- Cooling it down efficiently to maintain its integrity.

3. Machining

After forging, the camshaft undergoes precision machining to achieve the desired dimensions. This stage includes:

- Turning: Shaping the camshaft to its final diameter.

- Grinding: Creating a smooth finish on the lobes.

- Drilling: Making necessary holes for bearings and gear teeth.

4. Heat Treatment

Heat treatment is critical in camshaft manufacturing to enhance hardness and resistance. This process involves:

- Quenching: Rapidly cooling the camshaft in oil or water.

- Tempering: Reheating to relieve stress and improve toughness.

5. Finishing

The finishing stage may include various processes to improve performance, such as:

- Coating: Applying protective coatings to reduce friction.

- Balancing: Ensuring the camshaft is perfectly balanced to avoid vibrations.

Why is Quality Camshaft Manufacturing Crucial?

Quality in camshaft manufacturing directly impacts various engine performance aspects:

- Timing: Accurate camshaft production ensures that the valves open and close at the optimal time, enhancing combustion efficiency.

- Power Output: A well-manufactured camshaft can improve horsepower and torque, giving your diesel engine the power it needs.

- Fuel Efficiency: Precision in design and manufacturing can lead to better fuel atomization and a more complete burn, increasing fuel economy.

- Durability: High-quality manufacturing processes result in camshafts that can withstand the rigors of high-stress environments.

Innovations in Camshaft Manufacturing

The automotive industry is continuously evolving, and so is camshaft manufacturing. Recent innovations include:

1. Variable Valve Timing

An advancement in camshaft technology allows for the adjustment of valve timing based on engine speed, improving performance across a wider range of conditions.

2. Lightweight Materials

The trend towards using lightweight, composite materials helps reduce overall engine weight without sacrificing strength, enhancing efficiency and performance.

3. 3D Printing Technology

3D printing is making its way into camshaft prototypes, providing rapid prototyping capabilities that can aid in designing more effective cam profiles.

Choosing a Reliable Camshaft Manufacturer

When selecting a manufacturer for your camshafts, consider the following:

- Industry Experience: Look for manufacturers with a proven track record in camshaft manufacturing.

- Quality Certifications: Ensure that the manufacturer adheres to industry standards like ISO.

- Customer Reviews: Research past customer feedback to gauge the quality of the manufacturer’s products.

- Technology Utilization: A manufacturer that invests in modern technology is likely to produce superior products.

Conclusion

In conclusion, camshaft manufacturing is a critical aspect of diesel engine performance and efficiency. The intricate processes involved in creating high-quality camshafts underscore their importance in automotive technology. As the industry pushes for more innovations, the focus on quality manufacturing will remain paramount.

At Client Diesel, we understand the vital role that camshafts play in diesel engines. By providing high-quality diesel engine parts and partnering with reputable spare parts suppliers, we ensure that your engines operate at peak performance. Trust us for your camshaft needs and experience the difference that quality makes!